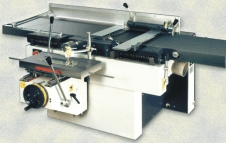

Robland SD510

Call For Price

For professional and industrial woodworkers. A strong, well-built precision machine that’s simple, easy to use and that will give good reliable service for many years to come.

- Description

- About Conway Saw

Description

For professional and industrial woodworkers. A strong, well-built precision machine that’s simple, easy to use and that will give good reliable service for many years to come.

Both professional and industrial woodworkers require a strong, well-built precision machine that’s simple, easy to use and that will give good reliable service for many years to come – The Robland SD510 Planer-Thicknesser-Mortiser.

- Strong cast iron deeply-ribbed for stability, the precision planed tables open together on powerful springs and are held open by a safety catch to prevent accidental closure.

- Edging operation is facilitated by 1500mm long x 200mm high anodized fence.

- Mounted on parallelogram type precision slides, both tables are fully adjustable up and down.

- For wet or damp timber, adjustable rollers can be provided, mounted in and easily removable from the thickness table. This option must be ordered with the initial order for the machine.

The heavy duty mortiser is equipped with steel guide axes and runs on 6 linear ball bearings, guaranteed for smooth and easy operation under the heaviest loads, and is absolutely maintenance free.

The chuck runs at 3000RPM and the in-and-out stroke lever of the table can be put at the low position for the machining of large workpieces, eg. doors.

Standard equipment

-

4 speeds controlled by a selector switch controlling both infeed and outfeed rollers.

-

4 columns anchored thicknesser table.

-

C.E. bridge guard with quick positioning mechanism is added for protection whilst surfacing.

-

Magnetic knife setter for its 4 knife cutter-block.

The optional digital read-out in 0.1mm can be ordered to replace the standard analogue readout.

The rise and fall of the thicknesser table, driven by an easy-to-use electric motor is standard on all machines. The analogue readout is standard on all machines.

Standard an all machines: heavy pushers on both in-and-outfeed side, and a 4knife cutterblock planer arbor. Optional “Wigo” cutter-block with 4 turnblades provides quick precision setting of knives. This option must be ordered with the initial order for the machine.

The thicknessing table is mounted on four columns to give stability. For wet or damp timber, adjustable rollers can be provided, mounted in and easily removable from the thickness table. This option must be ordered with the initial order for the machine.

| Planer | |

|---|---|

| Planer width | 510mm |

| Total length planer table | 2250mm |

| Spindle diameter | 100mm |

| Number of knives | 4 |

| Dimensions of knives | 510x30x3mm |

| RPM | 600RPM |

| Planer table height | 790mm |

| Length planer fence | 1100mm |

| Height planer fence | 150mm |

| Inclination planer fence | 90 – 45degree |

| Max. planer capacity | 6mm |

| Motor | 5,5kW |

| Tables | cast iron |

| Thicknesser | |

| Table size | 855x510mm |

| Max. thickness capacity | 250mm |

| Feed speed | 5-8-10-16m/min. |

| Diameter feeder rolls | 50mm |

| Electrical raise and fall thicknesser tabler | 75mm/min. |

| Table | cast iron |

| Mortiser | |

| Dimensions table | 600x300mm |

| Stroke: cross | 200mm |

| Stroke: in-out | 150mm |

| Stroke: up | 150mm |

| Capacity chuck | 0-16mm |

| RPM | 3000 |

| Total weight without mortiser | 900kg |

| Total weight with mortiser | 1000kg |

| Tables | cast iron |

| Standard Equipment | |

| 4 feeding speeds(electrical) | |

| 5,5kW motor | |

| Electrical rise and fall of the thicknesser table | |

| Pressure bars between feeder rolls and arbur | |

| Manual “star-delta” starting | |

| Magnetic knife setting jig | |

| Options | |

| Mortiser unit | |

| 7,5 kW motor | |

| Automatic “star-delta” starting for 5,5 & 7,5 motor | |

| Digital read out thicknesser | |

| Wigo planer arbor | |

| 2 Friction reduction rolld in thicknesses table | |