Sedgwick Spindle moulders SM3ii / SM4ii

Call For Price

A cast iron table mounted on a heavy duty steel cabinet provides maximum timber support and a stable and accurate base for anchoring the spindle, motor housing, and rise & fall mechanism.

All tables feature an anti-friction planed finish. The bearing housing, rise & fall assembly and motor mountings are also in machined cast iron.

The spindle is belt driven by an industrial motor and runs in 'sealed for life' bearings, which require only minimal maintenance.

- Description

- About Conway Saw

Description

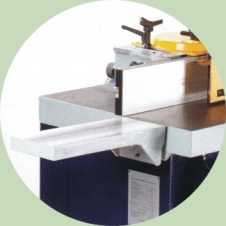

Construction

A cast iron table mounted on a heavy duty steel cabinet provides maximum timber support and a stable and accurate base for anchoring the spindle, motor housing, and rise & fall mechanism.

All tables feature an anti-friction planed finish. The bearing housing, rise & fall assembly and motor mountings are also in machined cast iron.

The spindle is belt driven by an industrial motor and runs in ‘sealed for life’ bearings, which require only minimal maintenance.

Ease of operation

The spindle rise & fall mechanism is operated by a hand wheel at the front of the machine. Spindle height is read from a scale and pointer on the SM3ii, and from a digital indictor on the SM4ii. The SM3ii features a cast iron ‘horseshoe’ type assembly with independently adjustable precision ground fence plates and movement indictors. The large capacity horseshoe on the SM4ii is cast aluminium for ease of handling. On the larger model a parallel guide provides movement of the entire fence assembly relative to the spindle, with measurement via a scale showing maximum usable cutter diameter in any position. Location plugs enable the fence position to be reproduced should the need arise to remove the fence altogether. On the outfeed side, the fence is micro-adjustable from -20mm to 25mm, again reading from a precision scale. 50mm diameter lobe handles clamp the extruded aluminium fence plates (precision milled and hard anodised) to the horseshoe, and facilitate their adjustment in or outwards of the tooling.

Changeover between the four spindle speeds is effected by quick and easy belt re-positioning. A viewing panel showing pulley speed is incorporated.

Versatility

The machine’s removable spindle allows the operator to select between 30mm and 1 ¼” diameter spindles, as well as offering the flexibility of optional router or tenoning spindles.

Safety Features

The full range is equipped with cast aluminium cutter guards, adjustable fore and aft in relation to the outfeed fence, and a robust shaw guard set with hexagonal mountings and steel ratchet handles. Twin outlets facilitate dust extraction from both the cutter well and fence locations.

Additional safety features include: automatic braking; starter with thermal overload no volt release protection and lock-off emergency stop; lockable isolator; electrically interlocked door; and a footstop.

Accessories

Table extensions

(SM4ii only) To provide increased support for long work-pieces. Manufactured in cast aluminium, a set of two extends the table length by 1000mm. They are fully adjustable to bring them level with the main working surface, and can easily be removed if not needed.

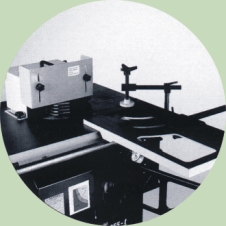

Sliding table

To provide a stable-moving platform for tenoning etc. The table is manufactured in cast iron, and runs on precision ground case hardened rollers and bearings. A mitre fence with 90-45degree adjustment, timber stop, and sturdy clamp are all incorporated. Table size: 740x300mm Stroke: 900mm Nett weight: 70Kg

Tenoning hood

To provide protective covering and a point of extraction (100mm) for cutters up to 350mm diameter. The lid and visor are both adjustable, and feature a carrying handle. Manufactured in strong sheet steel.

Stub spindle

For use when that part of the spindle which projects above the cutterhead (including the spindle nut) interferes with jobs which require stock to pass over the top of the cutterhead. The spindle is threaded internally, and the cutterhead secured with a cap screw and washer (diameter 50mm). Counterbored cutterheads are available for use with this option.

Router spindle

The router spindle is quickly interchanged, without disturbing the main spindle or bearings. Particularly valuable when machining small pieces, the unit comes with a ½” collet, nut and spanner.

Ring fence and safety guard

For safe machining of curved work-pieces. Comes complete with:

- Two interchangeable ring fences for large and small curves.

- Micro-adjustment of depth of cut via external controls.

- Transparent safety guard for clear vision of the work-piece.

- Integral 100mm extraction outlet and adjustable guard brush.

- Suitable for either direction of spindle rotation.

| Technical | ||

|---|---|---|

| SM3ii | SM4ii | |

| Table size | 850x600mm | 1000x650mm |

| Fence plates | 125x320mm | 155x440mm |

| Max. profiling cutter dia. | 210mm | 255mm |

| Max. cutterblock dia. | 125mm | 180mm |

| Max. tenoning cutter dia. | 320mm | 320mm |

| Max. cutter weight | 4Kg | 7Kg |

| Max. retrsctable tool size | 180x105mm | 180x105mm |

| Max. spindle projection above table | 125mm | 140mm |

| Spindle stroke | 90mm | 90mm |

| Spindle length | 125mm | 140mm |

| Spindle dia. | Optional | Optional |

| Spindle speeds | 1400, 3500, 6000, 8000rpm |

1400, 3500, 6000, 8000rpm |

| Tilt | n/a | n/a |

| Forward/Reverse | n/a | n/a |

| Motor rating 3 phase | 3.0Kw | 4.0Kw |

| Motor rating 1 phase | 2.2Kw | 3.0Kw |

| Motor full load current 3 phase | 6.1amps | 7.7amps |

| Motor full load current 1 phase | 16.2amps | 18.7amps |

| Automatic breaking | Standard | Standard |

| Max. power fed to take off point | n/a | n/a |

| Extraction outlets | 2@100 | 1@120 1@100 |

| Air volume required | 1530cmh | 1870cmh |